SEW-EURODRIVE’s TrueDNA: A turnkey drive solution that guarantees performance and reduces lead times

Jonathan McKey, National Sales and Marketing Manager at SEW-EURODRIVE

TrueDNA® offers a fully in-house, custom turnkey drive solution designed to meet the exact performance and reliability requirements of each application

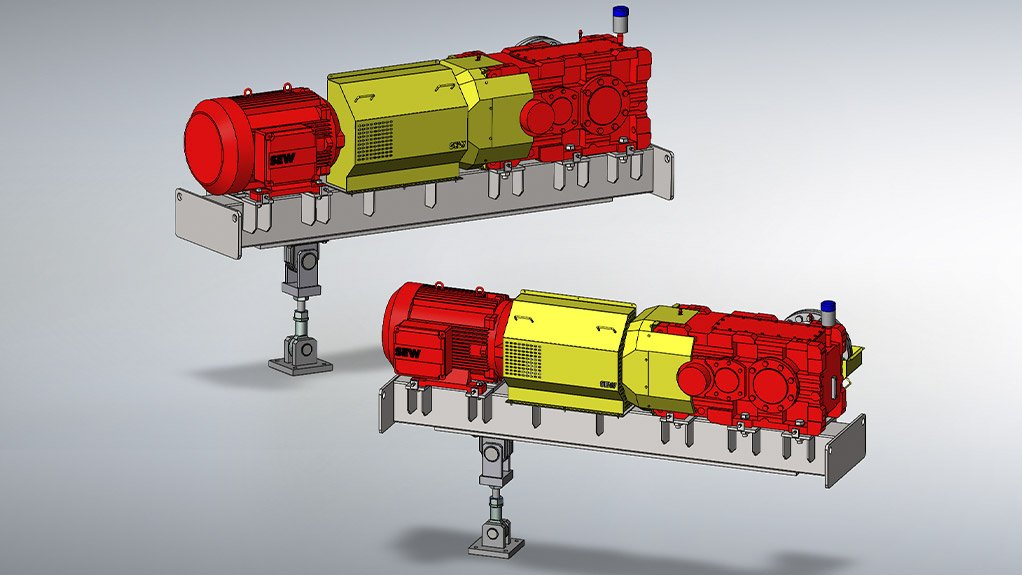

Customers can select their preferred base and coupling configuration, ensuring that the TrueDNA® solution is precisely tailored to their application requirements

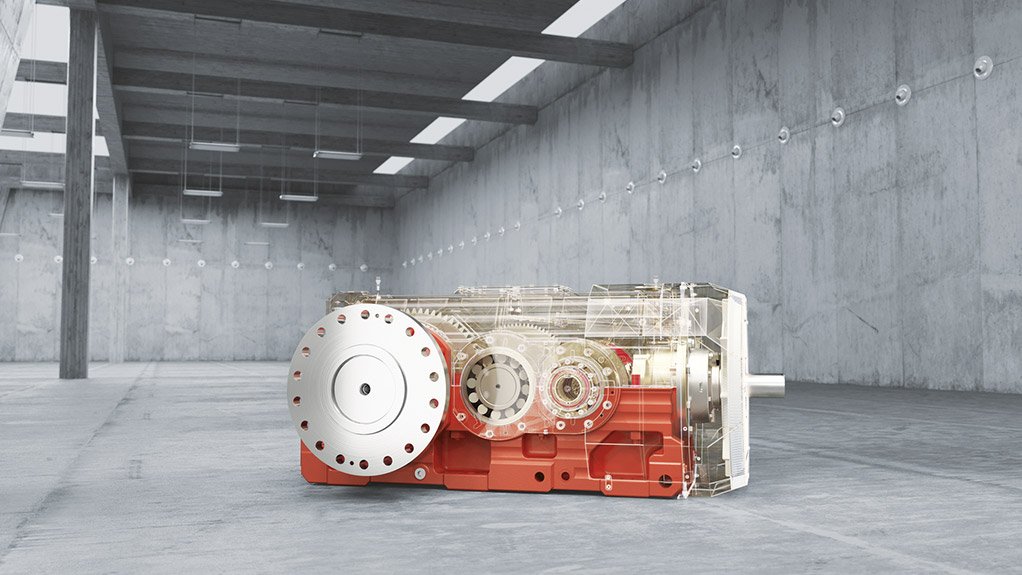

At the heart of the TrueDNA® solution is SEW-EURODRIVE’s innovative X.e series gearbox, engineered for enhanced efficiency, reliability and extended service

SEW-EURODRIVE’s GearOil lubrication technology ensures optimal performance, reduced wear and extended maintenance intervals for gear units operating in harsh environments

With locally stocked components and in-country assembly capabilities, customers benefit from significantly reduced lead times on their TrueDNA® drive solutions

This article has been supplied.

The introduction of SEW-EURODRIVE’s TrueDNA package responds directly to challenges faced by industry when mixing components from multiple suppliers in a drive solution. Performance inconsistencies, compatibility issues and support gaps have often compromised efficiency and reliability.

By offering a complete power pack solution from a single original equipment manufacturer (OEM) comprising the highest quality components, SEW-EURODRIVE ensures every component works in perfect harmony - guaranteeing optimum performance, streamlined support for extended warranties and peace of mind.

TrueDNA from SEW-EURODRIVE, a global leader in automation and drive technology, is a fully integrated turnkey drive solution designed for maximum flexibility, performance and efficiency. Engineered to cover a wide range of power, torque and speed characteristics, it can be easily adapted to drive various equipment across multiple heavy industries.

“A major advantage of the TrueDNA package is the significant reduction in lead times,” says Jonathan McKey, National Sales and Marketing Manager at SEW-EURODRIVE. “Because the majority of components are stocked items, customers can typically expect delivery within six to eight weeks from date of order - a notable improvement compared to traditional sourcing processes. This means quicker access to the latest technological advancements without lengthy delays, enabling customers to start production sooner, generate revenue faster and achieve savings on shorter timelines.

Each TrueDNA solution typically includes a base plate, gearbox, coupling and motor - all precisely matched to ensure seamless compatibility and optimum operational performance. Most customers opting for TrueDNA have selected the innovative X.e series gearbox, renowned for its enhanced efficiency, durability and energy-saving features.

The drive train is pre-filled with the customer’s lubrication of choice, although SEW-EURODRIVE recommends its latest advanced oil technology which offers extended lifetime, superior lubrication properties and improved efficiency in power transfer. With proper maintenance, customers can further reduce costs through extended oil change intervals.

“Choosing the TrueDNA package not only means acquiring cutting-edge drive technology, but also gaining additional value through extended warranties and complimentary maintenance training for end-user personnel,” McKey notes. “We are committed to ensuring optimum long term performance and supporting our customers’ operational excellence.

With TrueDNA, SEW-EURODRIVE redefines industrial drive solutions - simplifying procurement, optimising performance and delivering a future-ready package built to meet the toughest demands of modern industry.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation